Systems

Pressure vessels and piping systems are designed to contain certain pressure, which is called design pressure. PetrolValves can design the whole system to withstand the maximum wellhead pressure (MWP) however that will be a very expensive design especially when the fields are of high pressure. The effective design will be to step down the pressure as early as possible by using a pressure control valve. The remaining system downstream of the control valve will be in lower pressure to improve capacity and cost. During an upset condition such as fire, blocked outlet, pressure control valve failure and others can lead to excessively high pressure build up in the downstream system. When the pressure due to such an incident exceeds the design pressure of the downstream system, it can cause the rupture of the vessel or piping which in turn can cause severe hazard for human lives, plant assets or the environment. Therefore, it is essential to protect the system from the effects of over-pressure.

There are two ways of protecting the downstream system from over pressurization.

One, by using mechanical devices such as a pressure safety valve (PSV).

The other, by using a safety instrumented system such as high integrity pressure protection system (HIPPS).

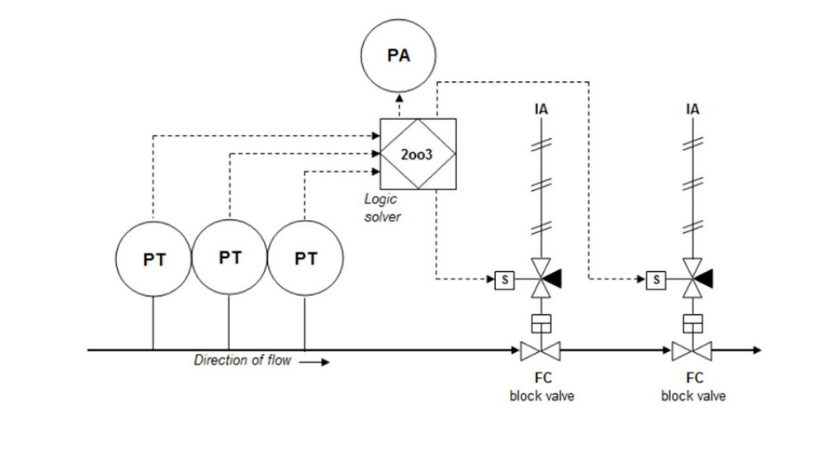

A HIPPS protects the downstream pressure vessel and piping systems by isolating the source of overpressure in the upstream. The time it takes to make this isolation is called Safety Instrumented System (SIS) response time or simply HIPPS shutdown time. This is usually half of time taken for the downstream system to reach its maximum operating pressure.

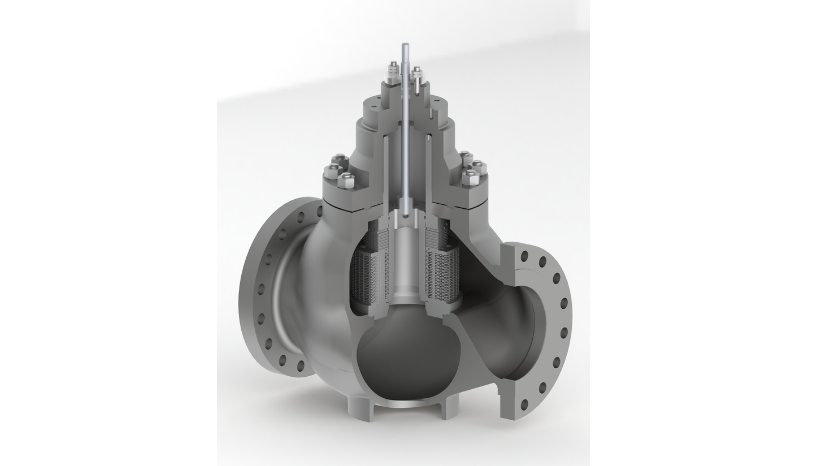

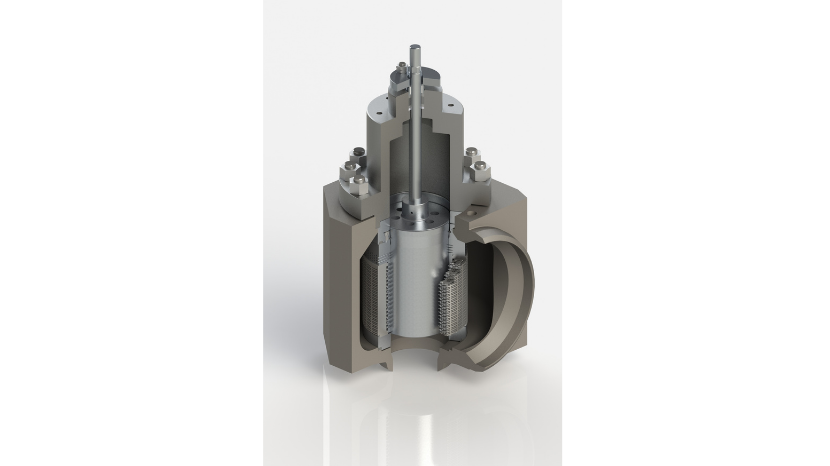

Therefore, the final element used in a SIS must be “proven in use” to ensure reliability of the SIS. The final element should close on demand, close within the response time and maintain the leakage rate specified (usually ISO 5208 rate A).

HIPPS System (valves, actuators, logic solver and instrumentation) shall be designed and manufactured to guarantee the following:

- Quick and safe operation on demand (Reliability)

- The SIL Level requirement

- Suitability for continuous operation (Availability)

- Compliance with process requirements (i.e.: function on Fail Safe mode, low pressure drop, low turbulence, etc.)

- Tightness level required to achieve adequate isolation

- Easy to operate and maintain (Availability)

Leveraging PetrolValves Group long experience and knowledge in valves and actuators manufacturing for critical services, we have delivered several HIPPS packages as System Integrator and single point of source for the entire “stand alone” emergency system.

PetrolValves boasts years of experience working with top systems components manufacturers and can work with any supplier according to end-user’s preference and requirements.

We can manage every step from engineering to delivery, including Special Testing and Safety Analysis.

PETROLVALVES is ISO 9001:2015 certified as System integrator for High Integrity Pipeline Protection System (H.I.P.P.S.)